Workshop Tour.

I am often asked if we run a shop or a workshop so I thought a short tour of the workshop might be interesting.

For the past 17 years I have been lucky enough to work exclusively from a large dedicated workshop in the grounds here at Newton Road, Rushden.

In the summer of 2023 we built a new workshop that would allow us to store the parts and equipment required to offer the highest quality of repair service to the latest GHD Gold and GHD Max irons.

Our old workshop now houses our 3D printers and CO2 laser.

Here are a few selected images showing the basic layout of the new workshop.

Picture 1.

Here we see the main bench, where all the work is completed. Digital microscope for the tiny parts we work with every day. Programming PC and CCTV iPad.

Along with a Fluke 179, PIC Processor tester, preheater and dual channel temperature meter. All repairs are filmed on a Panasonic 4K camcorder and the footage stored for 6 months.

Note the grey silicon mat, this ensures all items remain unmarked.

Picture 2.

Here you can see our Purex Fume extraction system with the blue cap. A new digital soldering station with micro tweezers, again, to enable us to work with tiny components.

A Weller soldering iron and hot air station complete the tools here.

Picture 3.

A wider view of the main work area.

Batt PAT portable appliance tester. I am a qualified PAT tester and have been repairing electronics since the early 1980s.

Specialising in Television and home electronics repairs since 1990 and for the past 11 years concentrating solely on GHD hair straighteners.

The most important part of a PAT test is the visual inspection, 99.9% of failures are visible, melted mains cable, cut mains cable, cracked or missing parts etc.

In 15,000 plus GHD hair straightener repairs I have had an actual electrical failure using the PAT tester just twice.

A test is carried out on every item that comes into the workshop. It is not a requirement to apply a Pass label in domestic situations, the pass or fail is recorded on the captured video recording!

Picture 4.

Main postage and packaging area.

Picture 5.

Here you can see our new 1000 Deg C kiln. This is used for repairing ceramic elements with broken wires.

Picture 6.

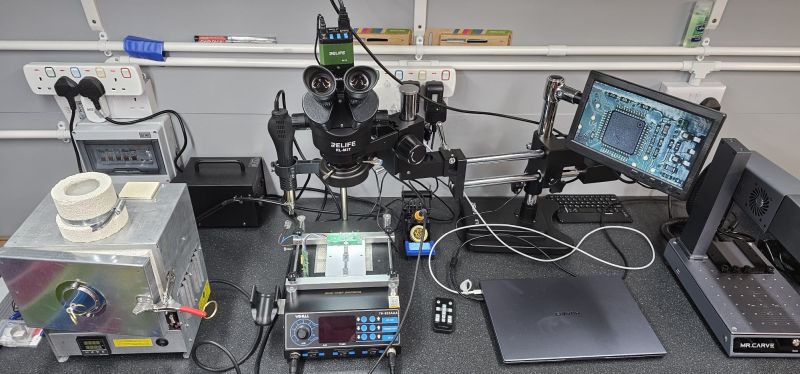

In this picture you can see our optical and digital microscope and rework station with preheater.

This equipment is required when changing the microprocessor on the GHD Gold and GHD Max range of irons.

After the microprocessor is changed it is programmed with our own code.

Picture 7.

A slightly different angle. Note the STM32 microprocessor being replaced on the monitor screen.

We can take still images or video through the microscope as required.

Picture 8.

Part of our extensive parts storage. Expanded greatly to accomodate all the GHD Gold and Max spares, arms, elements, PCB's, mains cables etc.

We have spares for the oldest GHD irons to the newest. Including the GHD Air 1.0 and GHD Helios hair dryers.

Picture 9.

We will often security mark items sold and personalise items for customers and here you can see our Mr Carve M1 Pro DPSS laser.

Picture 10.

After laser marking.

The workshop is fully protected by multiple CCTV systems and also benefits from a professionally monitored ADT alarm with Police and Fire Brigade response.

Anyway, I hope that was interesting and that you chose us to repair your GHD hair straighteners.

Workshop turnaround time is usually the same day.

Trevor Matthews. January 2024

Short URL for this page: